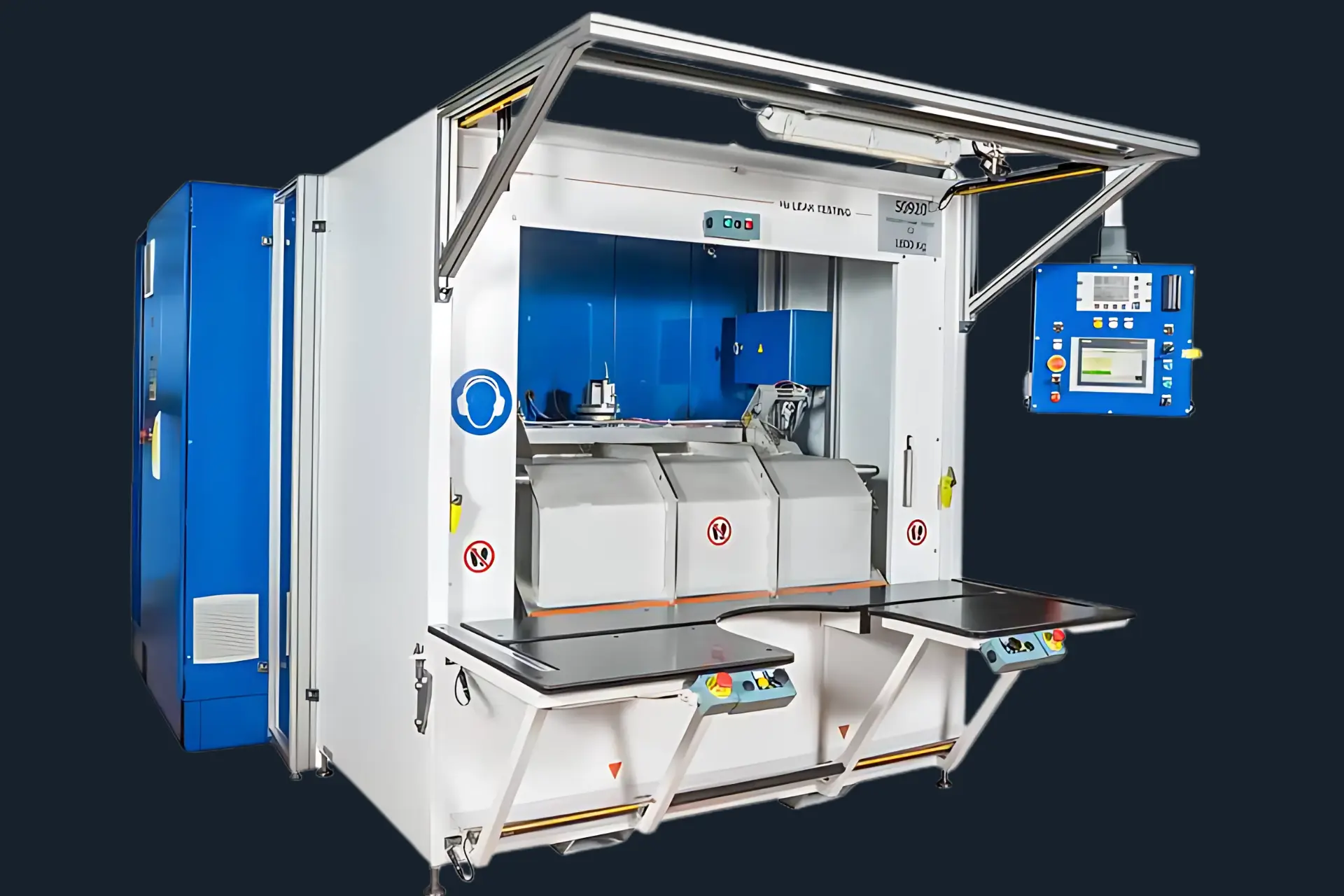

How to Get High Pressure Leak Test M/C 1000 Bar

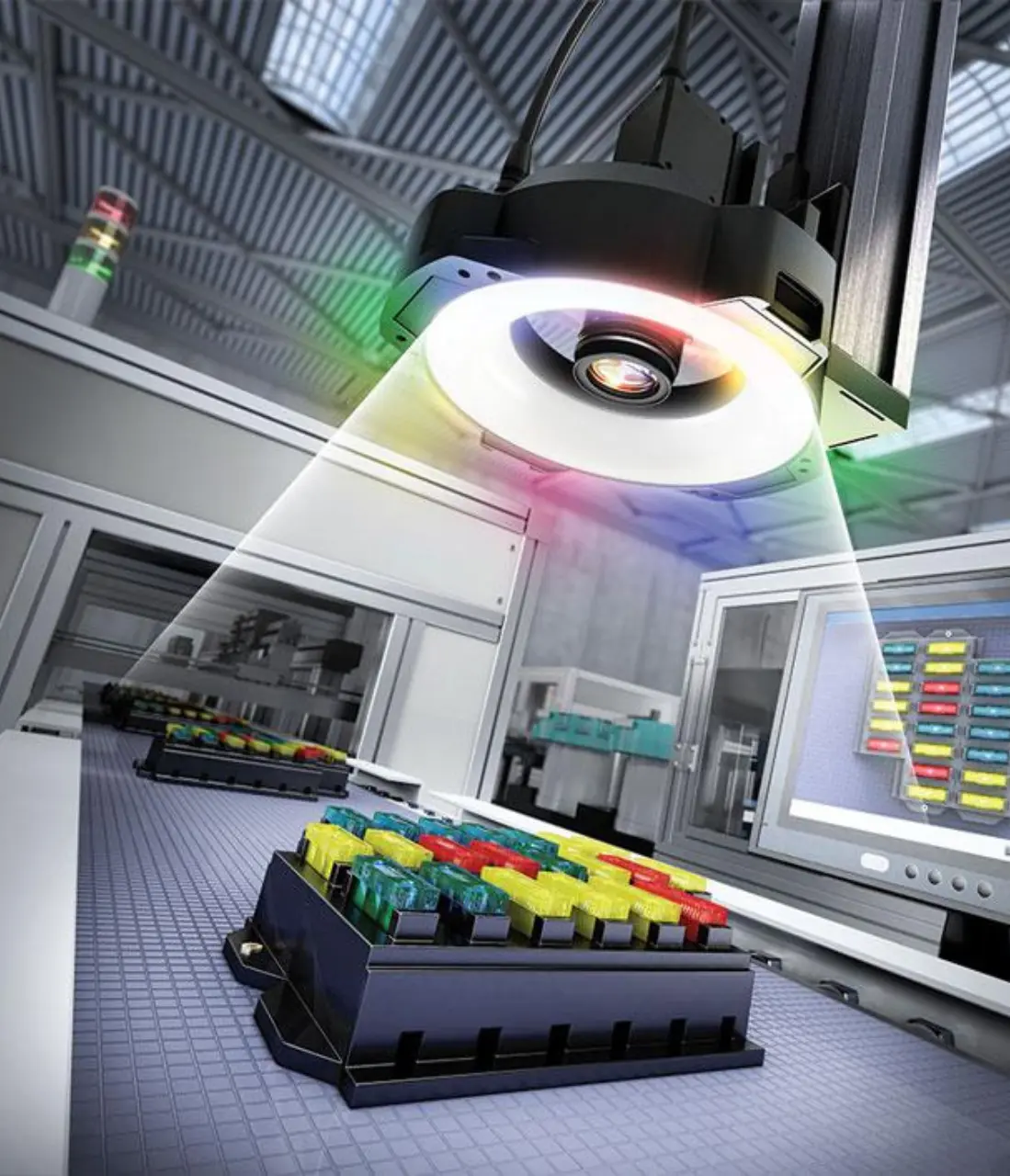

Introduction In industries like automotive, hydraulics, and aerospace, testing components under extreme pressure is not just a requirement—it’s a necessity. A High Pressure Leak Test M/C 1000 Bar helps manufacturers...

The 5000‑bar hydrostatic burst rig and 3‑axis vibration setup helped us validate new valve designs faster; programmable recipes reduced changeover time from 25 to 8 minutes.